- TOSIZE.lu

- Wood and sheet material

Timber boards

Furniture board is a collective name for various sheet materials, including timber board. The wood and wooden sheets in this group are widely used in furniture and interior design, hence the term furniture board. Furniture board is laminated chipboard finished with a fabricated top layer. Timber boards and solid wooden sheets consist of solid (bonded) elements.

Others were also looking for:

Order cut-to-size furniture board and timber board

Easily order cut-to-size furniture boards and timber boards online. Think of oak boards, mahogany boards of beech boards but also plain furniture boards such as furniture board white or furniture board black. These boards with plain or wooden appearance are characterized by their unique appearance.

Are you trying to achieve a plain matt black look or a warm, luxurious red cherry look? Have you found your favourite furniture board? We cut them to size with millimetre accuracy. You can have oak milled into an oval, circle, parallelogram or triangle and there are various options in terms of finishes. Quickly browse to your favourite board and see which shapes and finishes are available!

Timber and furniture boards: what is it?

Furniture boards include many different types of wood and wooden sheets. These boards can be used directly for furniture and other interior applications with little to no finish/treatment.

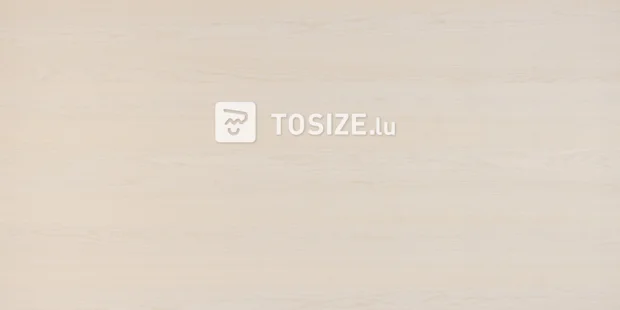

Furniture boards with a melamine top layer

A melamine top layer is a veneer layer of paper fibres, fused together with a melamine resin. This creates a hard plastic top layer. This top layer is applied to a chipboard or MDF core. A melamine top layer has a high density, which is what this top layer owes its hard and strong properties to. A melamine top layer is water repellent and, to a certain extent, heat resistant. In addition, this sheet material is easy to wipe and keep clean. No wonder it's a popular interior application.

In comparison with MDF, chipboard uses coarser wood splinters during bonding. Both sheet materials are relatively lightweight, easy to assemble, do not warp and are ready for immediate use.

Furniture board made of chipboard is ideally suited for decorative purposes. It is the standard sheet material to which a melamine top layer is applied. That is why it’s also known as ‘decorative chipboard’. The sheet materials are finished with a melamine top layer on one or both sides. See the product specifications for more information.

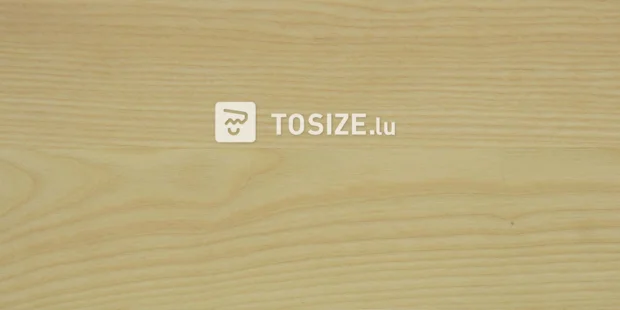

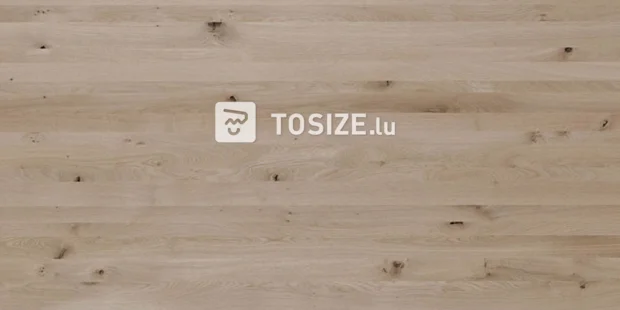

Wooden timberboards

Timberboard is a furniture board made of solid wood. Solid wooden sheets are robust and of high quality. Frequently used boards are oak boards, spruce boards and pine boards. All timberboards have a natural look. Perfect when you're looking for a warm or luxurious look for your DIY project or self-designed furniture.

The structure of timber and furniture boards

Furniture boards

Because furniture board is a collective name for many types of wood and wooden sheets, it is important to look at the individual properties of the sheet material. The vast majority of furniture boards consist of an MDF, chipboard or plywood core with a finished top layer.

Wooden timber boards

When we talk about timber boards, we mean solid wood furniture boards. There are different types of solid boards. One-piece boards, solid boards made up of continuous slats and solid boards made up of finger-jointed slats. Is a solid board made of one piece of wood too expensive? Then opt for solid boards composed of slats (small pieces of wood).

As you can imagine, a real solid board, consisting of one piece of wood, is a precious product. These boards are the result of years of tree growth and are only available exclusively. Fortunately, there are also affordable alternatives, so read on!

Solid boards made up of continuous slats are boards consisting of long strips (slats). Continuous slats are wooden strips along the entire length of the sheet. The strips are between 40 and 80 mm wide. These strips are then glued together in width, creating a long and wide board. Reference is also made to ‘DL solid’ when referring to boards with continuous slats.

In contrast to continuous slats, finger-jointed slats consist of small strips of wood. Finger jointing is a bonding technique. The long strips are glued together through collapsing figures, creating a long sheet. This figure resembles fingers, hence the term ‘finger jointing’. Finger-jointed boards are characterized by the fact that the board looks as if it is made of small pieces of wood.

By bonding the slats in this way, a wide and structurally strong board is created, which can be used for multiple applications. Reference is also made to ‘VL solid’ when referring to boards with finger-jointed slats.

Solid boards made from finger-jointed slats are a sustainable way of producing sheets. There is little waste because a lot of wood can be processed in the board. As said, real solid boards consisting of a single piece are rare, boards constructed using the finger jointing technique is an affordable alternative.

Properties of timber and furniture boards

Furniture boards with a melamine or veneered top layer

The chipboard or MDF furniture boards in our range all have a strong top layer. Will you opt for wooden sheets with a plastic melamine top layer or for naturally veneered wooden sheets? The difference? Melamine top layers are often inspired by trend-sensitive structures and materials, but standardized. A veneer top layer is a top layer made from a thin layer of real wood. Both have pros and cons. This means that with melaminated wooden sheets, there are no colour differences between individual sheets and they no longer need to be finished. Veneered wooden sheets have a warm, natural look and feel, where no two sheets are the same due to natural growth.

Boards made of natural materials

If you choose solid wood timber boards, it is important to take the properties of wood into account. Boards made of real wood parts can warp when exposed to temperature differences or used in damp rooms. Therefore, you should always treat these boards with lacquer, stain or oil. This way, you can enjoy your solid wooden sheets the longest. Also avoid contact with iron, copper or brass, as this can result in discolouration of the wood. If you want to join metal to solid wood, we recommend stainless steel.

Types of timber and furniture boards

Are you curious about the different types of timber and furniture boards in our range? We offer various fully finished chipboard furniture boards or wooden timberboards, fully cut to size.

Our range of timber and furniture boards includes the following types:

- Timberboard Ash A/B - Joined staves

- Solid three layers panel Ash

- Bamboo Caramel 1L Density

- Bamboo Caramel 1L Plain pressed

- Bamboo Caramel 1L Side pressed

- Bamboo Caramel 3L Density

- Bamboo Caramel 3L Plain pressed

- Bamboo Caramel 3L Side pressed

- Bamboo Caramel 5L Density

- Bamboo Caramel 5L Plain pressed

- Bamboo Caramel 5L Side pressed

- Bamboo Ecru 1L Plain pressed

- Bamboo Ecru 1L Side pressed

- Bamboo Ecru 3L Plain pressed

- Bamboo Ecru 3L Side pressed

- Bamboo Ecru 5L Plain pressed

- Bamboo Ecru 5L Side pressed

- Bamboo Natural 1L Density

- Bamboo Natural 1L Plain pressed

- Bamboo Natural 1L Side pressed

- Bamboo Natural 3L Density

- Bamboo Natural 3L Plain pressed

- Bamboo Natural 3L Side pressed

- Bamboo Natural 5L Plain pressed

- Bamboo Natural 5L Side pressed

- Bamboo Natural 5L Density

- Bamboo Tiger 3L Density

- Timberboard Beech A/B - Joined staves

- Timberboard Beech A/B

- Timberboard Beech C/C

- Solid three layers panel Beech

- Betuwemix Timber Panel

- Solid three layers panel Cherry

- Timberboard Maple A/B - Joined staves

- Solid three layers panel Maple

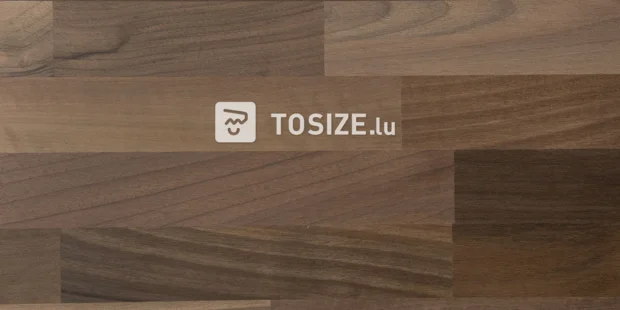

- Timberboard Walnut A/B - Joined staves

- Timberboard Oak A/B - Joined staves

- Timberboard Oak rustic - Joined staves

- Timberboard Oak A/B

- Timberboard Oak B/C

- Timberboard Oak rustic

- Oak timberboard Oak mix veneer

- Solid three layers panel Oak rustic

- Solid three layers panel Oak

- Solid three layers panel Douglas-fir rustic B/C+

- Solid three layers panel Pine light

- Solid three layers panel Pine rustic B/C+

- Solid three layers panel Pine rustic B/C+ brushed

- Timberboard Ash

- Timberboard Cherry

- Timberboard Iroko

- Timberboard Mahogany

- Timberboard Maple

- Timberboard Nuts

- Timberboard Pine dark

- Timberboard Pine light

- Solid three layers panel Walnut American

- Solid three layers panel Walnut European

Different colours and top layers of timber and furniture boards

Furniture boards with a melamine top layer

The chipboard or MDF furniture boards in our range all have a strong, hard melamine top layer. This plastic top layer means that the boards no longer need to be finished and are easy to wipe. This structure is fabricated, which makes many different colours and structures possible. From plain, matt looks to natural, busy looks.

Wooden sheets with a veneered top layer

Veneered wooden sheets are also available in various colours and structures. However, there is less choice here than with laminated wooden sheets. The colours of veneered sheets may vary per sheet due to the natural growth of the wood, which makes each sheet 100% unique.

Timber and furniture boards and moisture

Whether the timber or furniture board can withstand moisture depends on the core and the bonding of the sheet material. View the specifications per product to see whether the products are moisture resistant or can be used outdoors.

Wood is not naturally moisture resistant. By bonding the fibres, chips or slats, moisture-resistant wooden sheets are created. The type of glue makes this sheet material more resistant to moisture. Easily view all moisture-resistant variants of timber and furniture boards by using the filters on this page.

Available thicknesses of timber and furniture boards

Timber and furniture boards are available in various thicknesses, lengths and widths. View all available thicknesses in our range. In our web shop, you can order timber board 18 mm, timber board 19 mm, timber board 26 mm, timber board 40 mm, furniture board 18 mm and more, and have it cut to size.

Assembly and finishing of furniture boards and solid wood boards

Furniture panels are easy to assemble. They do not require pre-drilling. All solid wood species require some extra attention when it comes to finishing. Always finish the panel with a lacquer, stain or oil to minimise the risk of warping or discolouration. When mounting the panels it is recommended to use stainless steel. This prevents undesirable discolouration of the panel material. Read our tips here about finishing solid panels.

Common applications of timber and furniture boards

Timber and furniture boards are suitable for many decorative applications. Think of desktops, tabletops and countertops. The material is also very suitable for the realisation of furniture, cabinets or doors.

Solid wood in your interior

With solid wood, you quickly create a real eye-catcher in your interior. It's the natural, robust look that makes it unique. No two sheets are the same because of the natural growth of the material. A dining table, desk or piece of furniture.. each project becomes a little more special through the use of solid wood boards. The solid wood provides a warm appearance that comes into its own in every interior.

Alternatives to timberboards and solid wood panels

Is a solid wood panel not what you are looking for? Check out our entire range here; everything can be sawn or milled to the millimetre. Find the ideal type of wood for your next project!

Order solid or veneered wood?

A counterpart to solid wood is veneered board material. Solid boards consist of the same type of wood throughout, and so do the edges. Veneered board material has a thin real wood top layer, but is glued to another type of carrier. Veneered wood has a different core, for example MDF or multiplex. Because of this, the edges have to be finished extra with veneer tape. Veneered board material does not warp and is in some cases a more budget-friendly alternative.

Solid wood or furniture panel?

In terms of appearance, these board materials can look very similar. The main difference is that solid wood consists of real wood and melamine faced chipboard is manufactured plate material with a plastic top layer. This plastic layer is available in all kinds of colours and wood patterns, which makes it look like real wood has been used and gives you a lot of choice.

In terms of construction, solid wood panels are very strong (much stronger than chipboard). The real wood gives the material a robust feel in the home. However, this also makes it rarer and puts it in a different price bracket to chipboard. With solid panels, you should also be aware of discolouration and warping.

Are you a novice handyman? Then we recommend you also look at furniture panel. This panel material is much less hard than solid wood, is fully finished and is easier to assemble than solid wood.